FPB

Hourly output up to 1000 kg

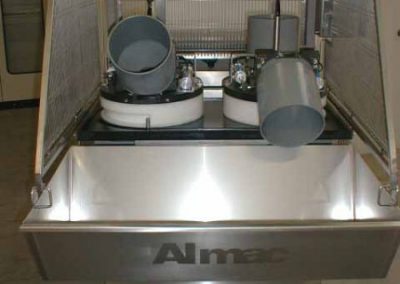

The Moulder mod. FPB/A is a machine which allows the automatic moulding and weighing of pasta filata cheeses to be obtained, such as:

CACIOCAVALLI WITH SMALL HEAD – SPHERICAL PROVOLE – CYLINDRICAL SALAMI, ETC….

The machine is completely managed and controlled by a PLC. Dough introduced into the hopper is pushed by two counter-rotating augers through an elbow pipe which is externally heated by a double jacket equipped with electrical heating elements. This system helps the extrusion phase. From this connection, dough is addressed towards the moulding and weighing head. From the head, dough is extruded into the moulding cup until to reach the desired weight. The PLC provides the control of the following automations: cutting, cups exchange and already filled cup discharge.

Construction Features

- Machine completely built in AISI 304 stainless steel and plastic materials certified for the food use.

- Parts in contact with the cheese are coated with non-sticking material.

- The moulding head is equipped with water double jacket, heated by an electrical heating element.

- The machine is equipped with one moulding head.

- Dismountable stretching water discharging filter.

- Dough feeding augers built to be easily dismantled without using any tool.

- Adjustable augers and moulding head rotation speed.

- Motorizations protected by AISI 304 stainless steel cases.

- Motorization equipped with spacer to allow the cleaning between the motor and the moulding chamber.

- Motorizations with watertight oil-bath speed variator, complete with case that allows, in case of oil leakage, the discharge to the ground thus avoiding any cheese pollution.

- Connections with bending radius built in such a way to avoid any stagnation point.

- PTC probe for detecting the water temperature into the double jacket

- PLC for the control of all sensors against accidents for the machine operation.

- Low tension fed external push-button panel, with controls subdivided according to the desired processing type for every section.

- Watertight electrical control panel with IP 65 protection degree, built in AISI 304 stainless steel, complete with electronic devices for the processing speed adjusting and the operator’s safety control.

- Dismantling easiness of the movable parts without using any tool and complete inspection possibility.

- Set of safety sensors against accidents to start the machine stop up in case of guards opening

Advantages

- Possibility to obtain a product using either the single cut or, up to the operator’s choice, the double cut (PATENTED system)

- The weight is determined by an ultrasound sensor that controls dough level without entering in contact with the cheese.

- Management and control of the cutting operations, already filled cups exchange and discharge, all by the PLC

- All parts in contact with the cheese are easily dismountable without using any tool to help washing and sanitizing operations.

- The whole processing cycle is automatically performed, thus avoiding unnecessary waiting times and increasing the machine productivity.

Technical data

Moulder mod. FPB

|

DATI TECNICI |

||

|

Formatrice mod. FPB |

||

| Dimensioni di ingombro (mm) |

Fpb / 2a Fpb / 4a Fpb / 6a Fpb / 8a Fpb / 10a |

2030 x 790 mm

2030 x 1340 mm 2030 x 1585 mm 2030 x 2100 mm 2030 x 2395 mm |

| Altezza (mm) |

“ |

1940 ÷ 2030 mm |

| Altezza di alimentazione (mm) |

“ |

da 1175 a 1265 mm |

| Altezza di scarico (mm) |

“ |

945 ÷ 1035 mm |

| Diametro coclee (mm) |

“ |

150 mm |

| Massa (a vuoto) (Kg) |

“ |

Da 200 a 1000 |

| Produttività (Kg/h) |

Fpb / 2a Fpb / 4a Fpb / 6a Fpb / 8a Fpb / 10a |

da 0 a 200 da 0 a 400 da 0 a 600 da 0 a 800 da 0 a 1000 |

| Ingresso aria |

“ |

Ø 6 mm |

| Tensione di linea (V) |

“ |

400 |

| Tensione circuiti ausiliari (V) |

“ |

24 V – DC |

| Frequenza (Hz) |

“ |

50 |

| Potenza elettrica installata (kW) |

“ |

da 2.5 ÷ 10 |

| Corrente assorbita (A) |

“ |

6.25 ÷ 25 |