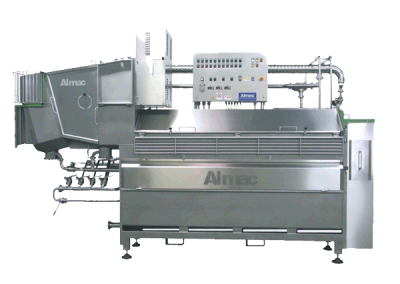

FTA 10

Hourly output up to 1500 kg

The FTA 10 stretcher is a machine optimal for the continuous production of pasta filata starting from minced curd at the right pH degree. This stretcher is suitable for the production of the following types of cheese:

PIZZA CHEESE – PROVOLONE, CACIOCAVALLO, SCAMORZA, ETC. – KASAR

Curd introduced into the processing chamber is conveyed by the augers towards the mixing section and transport speed is adjustable according to the desired type of cheese.

To reduce the stretching water temperature and to consequently decrease yield losses, the machine is equipped with an air-filled double jacket surrounding the whole augers chamber. After the sponge-down phase, pasta enters a mixing section equipped with diving arms working at adjustable speed for the stretching process completion and for passing, after a suitable stop, to the second mixing chamber equipped with rotative paddles. This last section allows a dough better fibrous structure to be obtained, giving it nerve and removing any eventual water pocket left by the diving arms section. The diving arms mixing chamber allows the cheese to be dried according to the needs, before its transfer to the moulding machine.

Construction features

- The machine is completely built in AISI 304 stainless steel and plastics certified for the food use.

- Parts in contact with the cheese are coated with non-sticking material.

- Mixing chamber equipped with rotative paddles and diving arms at variable speed to assign to the dough the desired consistency. Diving arms chamber discharging net to allow an easy evacuation of the stretching water, all this is adjusted by a stainless steel valve.

- Air-filled double jacket around the augers section to allow the thermal insulation from the external environment.

- Dismountable stretching water filter.

- Dough feeding augers built to be easily dismounted without using any tool.

- Adjustable dough transport speed according to the desired product.

- Motorization equipped with spacer to allow the cleaning between the motor and the stretching chamber.

- Stretching water preparation tank, heated by direct steam injection, managed by an electrovalve controlled by an electronic thermoregulator equipped on the control panel.

- Safety filter able to accumulate all machine discharges, easy to be inspected and sanitized.

- Stretching water level probe.

- Connections with bending radius built in such a way to avoid any stagnation point.

- Electropump for the stretching water circulation.

- Electropump for the stretching water evacuation.

- Stretching water thermoregulation.

- PT100 probe for detecting the stretching water temperature.

- Motorizations protected by AISI 304 stainless steel cases.

- Watertight electrical control panel with IP 65 protection degree, built in AISI 304 stainless steel, complete with electronic devices for the processing speed adjusting and the operator’s safety control.

- Motorizations with watertight oil-bath speed variator, complete with case that allows, in case of oil leakage, the discharge to the ground thus avoiding any cheese pollution.

- Dismantling easiness of the movable parts without using any tool and complete inspection possibility.

- Set of safety sensors against accidents to start the machine stop up in case of guards opening

Advantages

The advantages that can be obtained by using the stretcher mod. FTA 10 can be resumed as follows:

- High yield coming from the water lower quantity and temperature used during stretching.

- Uniformity of the stretching water temperature, assured by the thermoregulator equipped on the control panel and by the double jacket that insulates the processing area.

- Possibility to stretch with three different methods:

- Stretching water closed circuit

- Stretching water circulation with partial replacement

- Stretching water circulation with total replacement

- Use and control easiness that allows the machine to be used also by unskilled personnel.

Automatic C.I.P. washing plant connection arrangements

Technical data

Continuous stretcher mod. FTA 10

- Length (mm) 4290

- Height (mm) 2585

- Width (mm) 1040

- Feeding height (mm) 1560

- Discharging height (mm) 1200

- Augers length (mm) 2200

- Augers diameter (mm) 200

- Weight (empty machine) (Kg) 900

- Hourly production (Kg/h) 300 – 1500

- Line tension (V) 400V

- Auxiliary circuits tension (V) 24V DC

- Frequency (Hz) 50 Hz

- Installed electrical power (kW) 9 Kw

- Absorbed current (A) 33.75 A